Sheet Metal Solution located in Auckland and Christchurch is a privately owned company equipped with modern machinery and run by highly qualified tradesmen with over 20 years of experience in the sheet metal engineering field.

At Sheet Metal Solution we employ advanced manufacturing processes to ensure the highest quality in fabricating air ductwork. Our state-of-the-art machinery, including CNC machinery combined with expert craftsmanship by our workshop employees, allows us to deliver precision-engineered ductwork tailored to our clients' specifications.

- Permanent Angle: Fixed bends have a defined set angle ranging from 45degrees to 90 degrees

- Airflow Efficiency: Fixed bends help maintain airflow efficiency.

- Application: Commonly used in both commercial and residential HVAC systems.

- Ease of Installation: quickly and easily installed in various configurations

- Space Efficiency: its ability to curve allows for efficient routing in tight areas

- Reduced Noise: Flexible ducting can help minimize noise from airflow

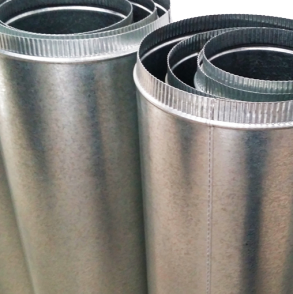

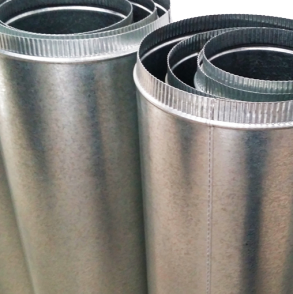

- Strength and Durability: Rolled pipes are typically strong and can withstand high pressure and temperature conditions.

- Sizing: Standard sizes range from Ø100mm- Ø600mm

- Customization: Please inquire for customized manufacturing

- Flexibility: Adjustable bends can be adjusted to various angles, typically ranging from 0 to 90 degrees, making them suitable for various layouts

- Ease of Installation: Adjustable bends simplify the installation process in complex or tight spaces.

- Equal Flow Distribution: Designed to provide balanced airflow

- Angles: Typically features smooth transitions at angles of 45 degrees to reduce turbulence and pressure loss

Also known as a T-Connector or T-Branch, is a component used to create a junction that allows airflow to split into two sources.

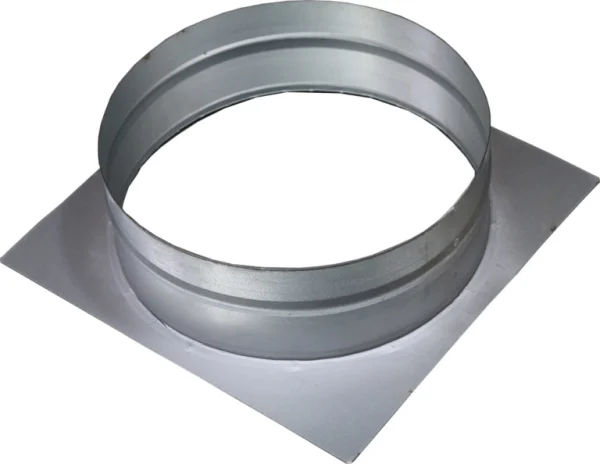

Flat Take Offs are used as a takeoff point on rectangular ductwork. These are manufactured using galvanised steel

Sheet Metal Solution Group is proud of our reputation for developing the skills of our employees and ensuring that all of the production services offered by us are carried out using the best precision manufacturing processes and equipment available to us.